What Is Yield Strength Of A Material

Hey there, curious minds and future engineers (or just people who like shiny things)! Ever wondered what makes your trusty bike frame so darn sturdy, or why that metal ruler doesn't instantly bend when you try to, well, make it bend? Today, we're diving into a super cool concept that's literally the backbone of so many things we use every single day: Yield Strength!

Think of it like this: every material, whether it's the fluffiest pillow or the toughest steel beam, has a breaking point. But before it goes all dramatic and snaps, there's this magical "give" point. That's our Yield Strength party trick!

The "Uh Oh, I'm Starting to Feel It!" Moment

Imagine you're stretching a rubber band. At first, it just gets longer, right? Easy peasy. But then, you keep pulling, and you start to feel a tiny bit of resistance. It's like the rubber band is whispering, "Okay, buddy, I'm still good, but I'm starting to work here!"

That "starting to work" point is super close to its Yield Strength. It's the moment the material stops just being stretchy and starts to permanently change shape. It's like it's saying, "Alright, fine, I'll bend a little, but don't push me too far, or there will be consequences!"

It's Not About Breaking, It's About Bending!

Now, here's the fun part: Yield Strength isn't about the material shattering into a million pieces. Nope, that's the ultimate tensile strength, a whole different adventure for another day!

Yield Strength is all about that point where the material starts to get a little bit, shall we say, permanently kinked. It's like trying to fold a piece of paper too many times – it keeps its shape, but you can see the fold lines forever. For metals, it means they won't spring back to their original form anymore.

Think of it like your favorite pair of jeans. They're super comfortable and mold to you, but if you stretch them way too much, they might end up a bit saggy and never quite go back to their perfect fit. That "sagging" point is like Yield Strength!

Why Does This Even Matter? It's Everywhere!

This "give" point is incredibly important for designers and engineers. They need to know how much force something can take before it starts to permanently deform.

Take bridges, for instance. Nobody wants a bridge that starts to droop like a sad noodle in the middle! Engineers use the Yield Strength of the steel and concrete to make sure the bridge can handle all the cars, trucks, and even those occasional parades without going "uh oh."

Even your humble coffee mug has a Yield Strength! If you accidentally whack it on the counter, it might chip or crack (that's the breaking point), but it's unlikely to suddenly become a wobbly mess unless you're applying some truly heroic force.

Materials Have Personalities!

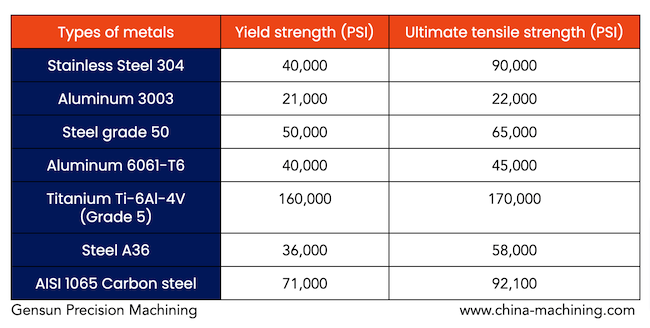

Every material has its own unique Yield Strength. Some are like stubborn mules, requiring a TON of force to even start bending. These have a high Yield Strength, like that super-tough titanium used in airplanes.

Others are more like a shy mime, easily persuaded to change their shape with a gentle nudge. These have a low Yield Strength, like some softer plastics or even certain types of foam.

This is why we have so many different materials! We pick the one with the right "personality" for the job. You wouldn't build a skyscraper out of marshmallows, and you wouldn't want a bouncy castle made of granite, right?

It's like choosing your workout buddy! Some people are powerlifters who can lift incredibly heavy weights (high Yield Strength). Others are more like yogis, who can bend and twist with amazing flexibility but might not be able to hold a massive weight for long (lower Yield Strength).

The "Stretch and Snap" Tango

So, let's revisit that stretching idea. When you pull a material, you're applying stress. Up to its Yield Strength, the material mostly just stretches elastically. This means when you stop pulling, it snaps right back to its original shape, like a superhero returning to their pose.

But once you push past that magical Yield Strength, the material enters the "plastic deformation" zone. It's like it's permanently saying, "Okay, I've been stretched, and I'm not going back to how I was." It’s still holding together, but it’s got a souvenir from your efforts.

And if you really go for it and keep pulling, you'll eventually hit that ultimate breaking point. But that first little bit of permanent "give"? That's the headline act of Yield Strength!

Measuring the Mighty "Give"

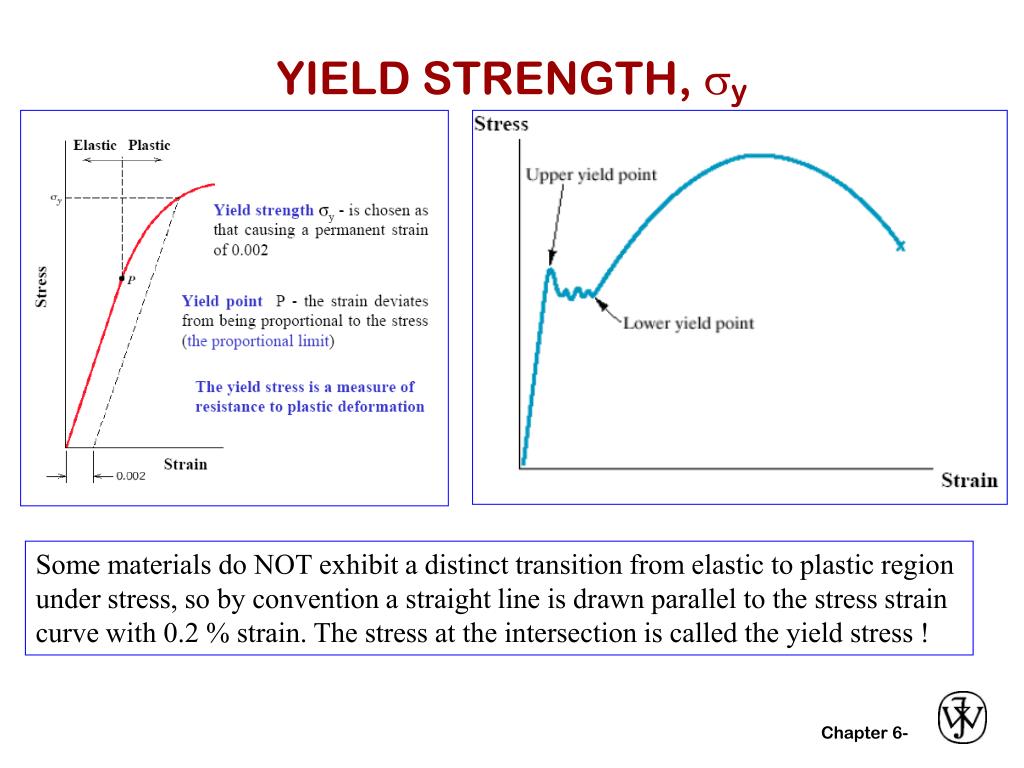

How do scientists know this magic number? They do fancy tests, of course! They'll take a piece of the material, clamp it down, and pull it with machines that are way stronger than your average gym rat.

They carefully measure the force and how much the material stretches. By looking at the graph of force versus stretch, they can pinpoint that exact moment where the straight line starts to curve – that's the Yield Strength in all its glory!

It's a bit like trying to figure out how much sugar your grandma secretly puts in her cookies. You have to taste a lot of them (don't worry, it's delicious research!) to get a really good average.

Imagine you're trying to find the exact spot on a trampoline where it starts to sag permanently after a giant jump. That’s kind of what scientists are doing, but with super-strong machines and very precise measurements!

The "Not Quite Broken, But Definitely Changed" Club

So, in a nutshell, Yield Strength is the point where a material says, "Okay, I can handle a bit more, but I'm not going to pretend I'm perfectly fine afterward." It's the material's way of acknowledging that it's been through something and is now in a new, slightly bent state.

It's a fundamental concept that allows us to build everything from your smartphone case to the towering skyscrapers that grace our cities. Without understanding Yield Strength, our world would be a whole lot wobblier and less reliable!

So next time you see a sturdy bridge, a strong chair, or even just a well-made tool, give a little nod to Yield Strength. It’s the unsung hero that keeps things from going spectacularly wrong, one bend at a time!